Despite the challenges we undoubtedly all experience, we acknowledge the enormous opportunities that exist for our (high-tech) manufacturing industry in the Netherlands. It is time to peel off our layers of identity and see what we are really capable of. To see our unique competences and the means we have to lead the transformation. To use our current business to finance our innovation journey and create our own sustainable future, for our industry and our own companies. Time for the Dutch manufacturing industry to step up and use its expertise, its people and its infrastructure to explore these new business fields and make our industry sustainable.

An innovation journey based on existing competences

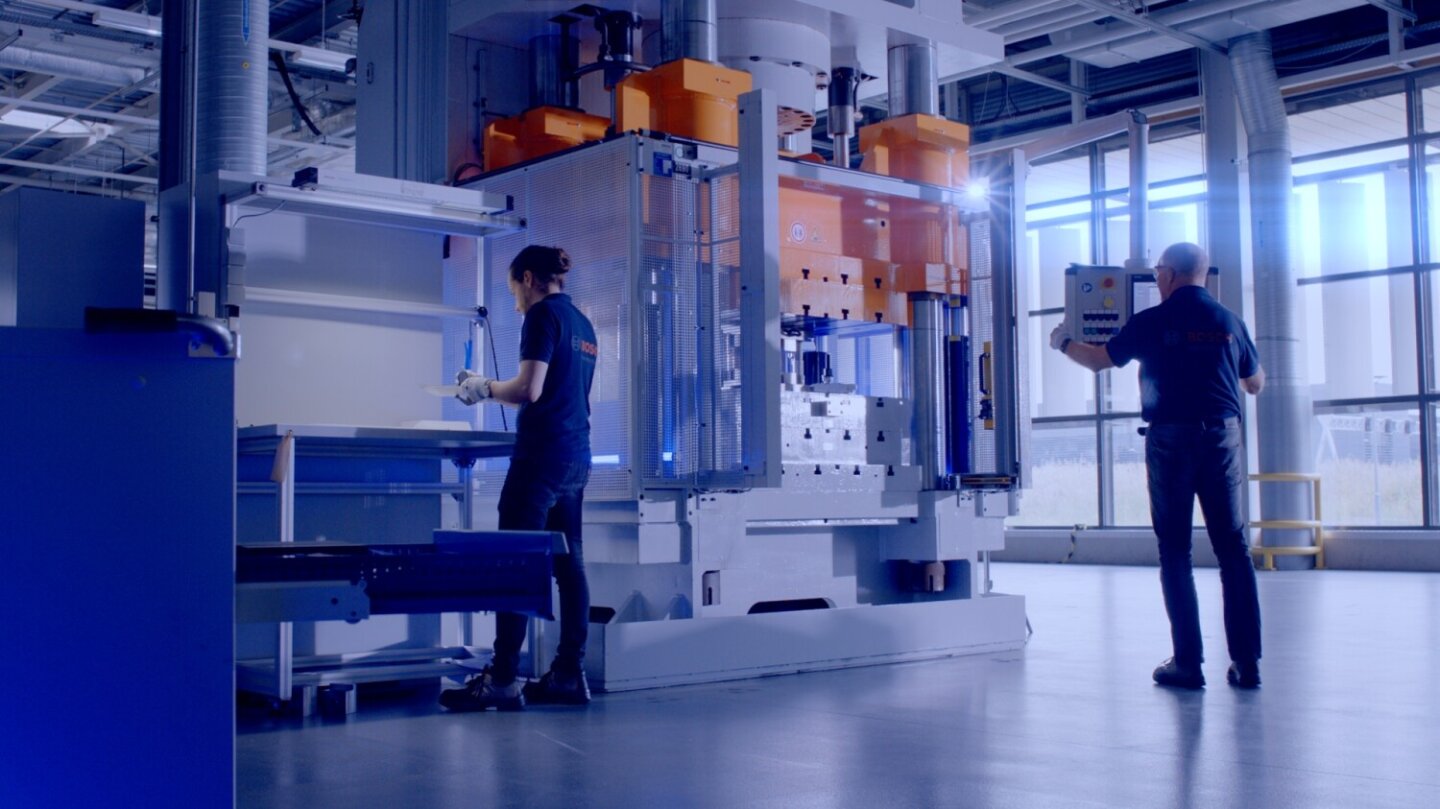

It is that innovation journey that we embarked on just under a decade ago. At the time, Bosch Transmission Technology in Tilburg, market leader in the development and production of pushbelts for continuously variable transmissions was still growing. Even breaking sales and production records year after year. Despite this highly successful business situation, we started investigating which technologies are needed in the future, which we can make with our specific engineering and manufacturing skills.

We looked for the sweet spot to create our innovations: high quality thin metal products for sustainable technologies. Technologies which can only be created with specific material science and production processes,we already master. There was no shortage of ideas and within a decade, we expanded the product portfolio to include new high-tech thin metal components such as e-stacks for electric motors and air foil bearings. The e-stack, a stack of delicate electrical steel sheets for high-performance electric machines, forms the core of an electric motor and can be used in many segments and industries. The air foil bearing is, among other applications, part of an electric air compressor that reaches speeds of over 100,000 revolutions and can be used in, amongst others, fuel cell systems. Our series production of e-stacks and air foil bearings began at the end of 2023. In 2025 the production of high-tech metal plates for fuel cells will start.

Thanks to the knowledge that has been built up during the development of electrolyser stacks and through developing plates for fuel cells and electrolysers, we also became the development center for electrolyser development within Bosch. We believe that our strength is that we drive ourselves to think and act as an innovative entrepreneur by looking at potential new business while benefitting from the processes and skills of an established business under the wings of Bosch. Together with our pushbelt, a very successful and established product in the market, we have the right mix to create a sustainable future for our company.

We invite the Dutch manufacturing industry to join us on this innovation journey. We believe that we have the right people and competences right here in our region to drive this journey of transformation in the automotive industry and beyond.

This is an article from the RAI Automotive Industry Magazine about the Dutch automotive industry. Want to read more?